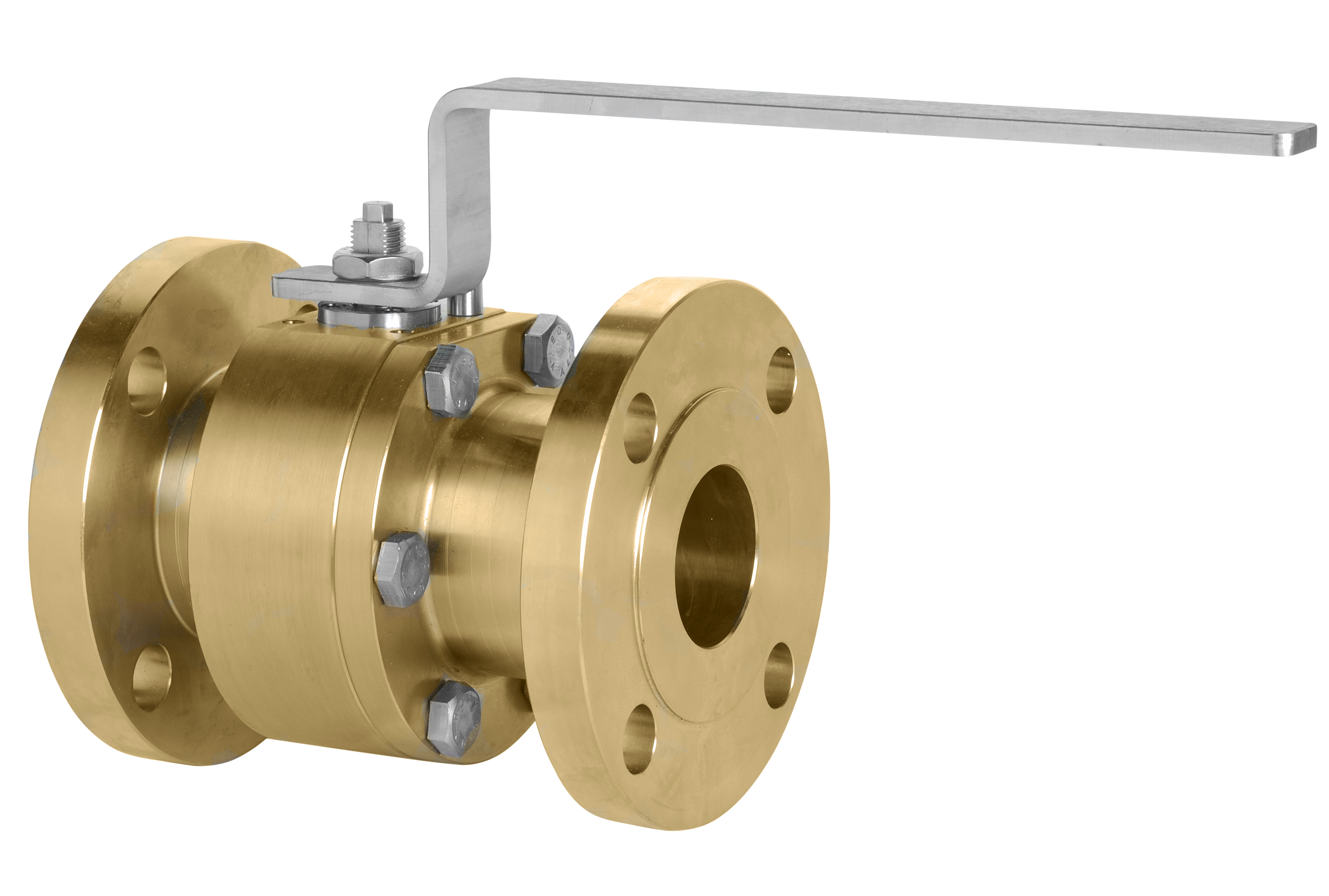

- Class 150 to Class 2500

- Size Range ¼” thru 10” (Class Dependent)

- Full and Reduced Bore

- Body Wall Thickness ASME B16.34, Forged or Cast Versions

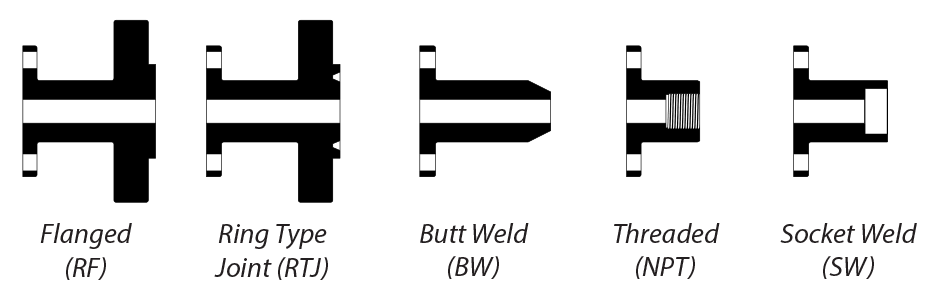

- End Connections: SW, BW, RF, RTJ, NPT, BSP, Special

- Fire-Safe Design API 607

- Blowout Proof, Low Torque Guided Stem Design

- Anti-Static Device and Live-Loaded Packing

- Fugitive Emissions ISO 15848

- Wide Range of Soft Seat and Metal Seat Options

- Manual, Electric, Pneumatic, or Electro-Hydraulic Operators Available

- Custom Face-to-Face Lengths Available per Customer Requirement

Literature

Certifications & Compliance

Sesto Valves are designed and manufactured to internationally recognized standards including but not limited to the following:

Design: API 6D, API 608

Fire Testing: API 607, API 6FA, BS 6755 Part II

Testing: API 598, ISO 5208, BS 6755 Part I, BS 6364

Marking: MSS-SP-25, PED, API 6D

Certifications: API607, SIL, NACE, MR0175, PED, ISO 15848

Partial List of Applications

- Oil & Gas Pipelines

- Refineries and Petrochemical Plants

- Power Generation

- Gas and Coal Fired Turbines

- Gas Measurement Systems

- Offshore Platforms

- Cryogenic Service Applications

- Emergency Shut Down Valves

- Pulp & Paper

- Mining

- Boiler Steam and Drain Applications

Fire-Safe &

Fugitive Emissions Certified

Packing arrangement is Fire-Safe for critical applications and Fugitive Emissions ISO 15848 certified.

End Connections

Why Sesto?

Precision Machined Forged Body

The forged body eliminates the possibility of leakage due to poor castings. Precision finish machining keeps tight tolerances to ensure secure assembly for high pressure, critical applications.

Ball/Seat Lapping

Lapping seats to the ball ensures tight tolerances, improving shut-off sealing capability while lowering torque requirements.